As we age, our pores and skin The natural way loses elasticity and firmness because of a decline in collagen and elastin creation. This often leads to sagging skin, good lines, and wrinkles—Particularly within the experience, neck, and round the eyes. The good thing is, modern day enhancements in aesthetic medication offer you non-invasive remedi

Reclaim Youthful Pores and skin with Non-Surgical Skin Tightening at Princeton Medi Spa

As we age, our pores and skin Obviously loses elasticity and firmness as a result of a drop in collagen and elastin generation. This generally results in sagging skin, fine traces, and wrinkles—especially within the facial area, neck, and throughout the eyes. Fortunately, modern day advancements in aesthetic drugs supply non-invasive alternatives

Reclaim Youthful Skin with Non-Surgical Pores and skin Tightening at Princeton Medi Spa

As we age, our skin Obviously loses elasticity and firmness because of a drop in collagen and elastin manufacturing. This often contributes to sagging pores and skin, fine lines, and wrinkles—Specially on the confront, neck, and round the eyes. Luckily, present day advancements in aesthetic medicine present non-invasive solutions. At Princeton Me

Reclaim Youthful Pores and skin with Non-Surgical Skin Tightening at Princeton Medi Spa

As we age, our pores and skin Obviously loses elasticity and firmness on account of a drop in collagen and elastin creation. This usually causes sagging skin, wonderful strains, and wrinkles—Particularly to the encounter, neck, and throughout the eyes. The good thing is, modern day progress in aesthetic drugs provide non-invasive remedies. At Pri

Reclaim Youthful Skin with Non-Surgical Pores and skin Tightening at Princeton Medi Spa

As we age, our pores and skin naturally loses elasticity and firmness because of a drop in collagen and elastin generation. This generally contributes to sagging pores and skin, fantastic lines, and wrinkles—Particularly on the facial area, neck, and throughout the eyes. Thankfully, contemporary progress in aesthetic medicine provide non-invasive

Amanda Bearse Then & Now!

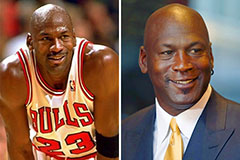

Amanda Bearse Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Barbara Eden Then & Now!

Barbara Eden Then & Now! Nadia Bjorlin Then & Now!

Nadia Bjorlin Then & Now!